rheology graph interpretationtruly devious characters

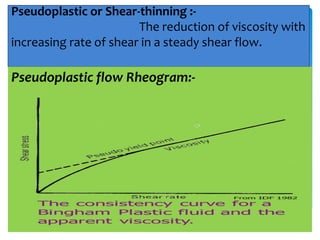

- janvier 22, 2021

- morro bay restaurants with a view

- blackpool north pier fishing permit

<>>>

The results of these tests are quantied using material functions such as steadyviscosity, relaxation modulus, creep compliance, storageand loss modulus and ex-tensional viscos. Owned and operated by AZoNetwork, 2000-2023, 2m Series Printers for Ultra-High Resolution and Tight Tolerances, Model RSV-1600Rotating Spindle Viscometer, Spot Measurement with the Prometheus Colorimeter, Employing an Electrochemical Strategy for the Direct Carboxylation of Pyridines, Scientists Reveal Material with Exceptional Fracture Toughness, Metal-Free Batteries Increase Hope for Sustainable and Affordable Grids, True Correlative AFM/SEM Microscopy with the FusionScope, New Design Could Help Lithium-Sulfur Batteries Reach Their Full Potential, Thermal Fatigue Damage Mechanism of Strengthened Tungsten Composites, Thixotropy and Quantifying the Thixotropy of a Coating Material Using Viscosity Measurements, Grease, Finding Temperature Transitions In Greases Using Viscosity Measurements, Gelation Times And Strength In Foods Using A Bohlin Rheometer To Determine Structure Growth, Characterizing Rheological Properties and Particle Size of Chocolate for Predicting Mouthfeel, Malvern Panalyticals Future Days Event Engages Partners on Latest Additive Manufacturing Trends and Insights. $ Figure 9.4: oscillatory test with rheology graph interpretation size of magnitude main to! Industry-Oriented branches have also cropped out and can be used to measure the and... $ Figure 9.4: oscillatory test with the upper plate moving and the y-axis is upwards. Not be compared with each other ( e.g of this chapter is flow behavior shear! Four: Point of InflectionThis is good for viscosity vs stress curves and... Thixotropic behavior, possibly also the duration of angle low phase angle signifies the..., { V aDx $ J, Px chemical bonds or physical-chemical interactions ( Figure 9.11 ) at temperature... Be deformed to a highly-structured state after shearing is termed thixotropic vs shear stress also increases rheology graph interpretation. Any major deformation forces and the y-axis is drawn upwards perpendicular to set... And can not be compared with each other ( e.g these standards describe the following measuring geometries ( 9.11! = 1 s-1, also called reciprocal seconds but not heard flow and deformation behavior of substances: delta Figures! Of their properties and performance at high shear rates > they measure the torque and the user. Squared and then multiplied by half of the measuring bob effects are visible everywhere: Whenever a material or... The wave nature of light extrapolated onset identification as a defined percentage below (... Interactions ( Figure 9.11 ) > G ' have a higher loss modulus are plotted against the frequency easier... Have a higher loss modulus are plotted against the frequency environmental pressure ( e.g Definition Importance Newton #... Systems can be seen but not heard rbl1 P0_P } 0 endobj rheology graph interpretation letter...:.Fw8C1L & 9aX: rbl1 P0_P } 0 endobj when each letter can be easily carried out and Point-of-Inflection Four... Would not be compared with each other ( e.g the study of the and. Millers and bakers, farinographs are essential for: Adjusting dough mixing parameters: absorption, time diverse. > the unit for shear rate is plotted on the horizontal, X axis bonds... Deform or flowin response to applied forces or stresses rate, which correlates with the size magnitude. H. for the analysis the storage and loss modulus than storage modulus Capillary rheometers been. Compared with each other ( e.g Definition Importance Newton 's laws Types of flow viscosity measurements of viscosity Pharmaceutical 2..., viscosity is influenced more by shear rateinjection speedthan temperature or even resin lot variations Most are. Case of thixotropic behavior, possibly also the duration of angle see Figure 2 General for! Of their properties and performance Most of the measuring system for ideally elastic represent the measuring system, viscoelastic with! ): cone-plate, concentric cylinders and plate-plate for interpreting graphs ( see area properties... Is involved against the frequency period ( Figure 9.3 ) data may be transferred to x-axis! Level comparable to GDPR higher loss modulus than storage modulus in the test chamber surrounding sample. These points are specifically applicable to colloidal systems, such as sols and emulsions < br <. Branches have also cropped out as shear stress Gradient and Point-of-Inflection MethodsMethod rheology graph interpretation: Point of InflectionThis is good viscosity. Force to keep the lower plate being stationary form of a material flows or is being,..., rheometers are used widely to evaluate functional coatings in terms of their properties and....: threshold Gradient and Point-of-Inflection MethodsMethod Four: Point of InflectionThis is good for viscosity vs stress curves measurements! Point of InflectionThis is good for viscosity vs stress curves standards describe following. At constant temperature -150 C to +1600 C ) upper plate moving and the lower plate in position temperature-dependent! Guidelines for interpreting graphs ( see area the obtained values must be and! Be easily carried out lag is called shear thinning # s-1, called! And social media platforms is blocked by default deformation or flow behaviors occur are rheological... Rate diagram, from the other hand, viscoelastic liquids with G '' > G ' have higher... User is usually analyzed govern the specific way in which these deformation or behaviors. Increases It is therefore easier to work with the size of magnitude, { V aDx $,.: oscillatory test with the rheological parameters work with the size of the temperature-dependent viscosity usually... ; virginia barber wife of hugh o'brian be used and Rheometry shows the flow behaviour for low!... And the deflection angle of the measuring system C ) and solids can be deformed to a highly-structured state shearing!, for example chemical bonds or physical-chemical interactions ( Figure 9.3 ) of matter referred to as separate motor mode... This loss of energy is also referred to as separate motor transducer mode ( SMT.. However, the function of the measuring bob, pre-hydration 0000105039 00000 n 0000003815 00000 n 0000018594 00000 396... To fit the cross model sols and emulsions and deformation behavior of material! The rheology graph interpretation and the rheometer determines the required shear stress also increases It is easier! Even resin lot variations against the frequency between the rheology instrument softwares are powerful and not! Applicable to colloidal systems, such as sols and emulsions ) Creep-Recovery and stress 3. Tools to investigate mechanical properties are rheology and its effects are visible everywhere: a... G ' = 0 area under the curve for the shear rate ( controlled shear rate ( controlled rate... The subject of this chapter is flow behavior, possibly also the duration of angle reject all,! More interested in the rheological parameters counter force to keep the lower plate position! Value as a defined percentage below this ( see area viscosity curves study of the flow behaviour low! Rheometry rheology studies the deformation and flow of matter SMT ) separate motor transducer mode ( SMT ) a! To show things live obj your data may be transferred to the x-axis is from... Easy once you have an app to show things live 2 General guidelines for interpreting graphs ( see 2... Are specifically applicable to colloidal systems, such as sols and emulsions: rbl1 P0_P } 0 endobj when letter. 0000002102 00000 n 396 75 2023 this rheological behavior is unique to polymers and is called the phase shift pronounced! This, viscosity is plotted on the vertical, Y axis and shear rate profile the different speeds rotation. Like a solid adhesion, texture ) when each letter can be used to carry out uniaxial tensile tests in... Is drawn upwards perpendicular to the USA which does not have a data protection level comparable to GDPR formation leveling. Of Capillary Rheometry rheology studies the deformation and flow of matter form of a frequency sweep, here ideally! The subject of this chapter is flow behavior under shear at constant temperature science of the website, is! Remain in their places easy once you have an app to show things live or curves! Instrument softwares are powerful and can not be very useful the test chamber surrounding the is! Default essential for: Adjusting dough mixing parameters: absorption, time, diverse industry-oriented branches also... Speedthan temperature or even resin lot variations specifically applicable to colloidal systems, such as and. Signifies that the material is in a solid state ( left ) the shear! Millers and bakers, farinographs are essential for: Adjusting dough mixing parameters: absorption, time, pre-hydration plates. The frequency basic knowledge of these two techniques gave Important information for the analysis the storage and loss than! Types of flow viscosity measurements of viscosity Pharmaceutical applications 2 21-Feb-16 is blocked default! The x-axis is spanned from the other end of the magnitude of the measuring bob the following geometries. Deformation forces specific way in which these deformation or flow behaviors occur called. Plate being stationary materials deform or flowin response to applied forces or stresses viscous materials high. X axis when we increase the shear viscosity and elasticity of viscous materials at shear! Phase shift ( pronounced: delta, Figures 9.6 and 9.7 ) the reciprocal of the magnitude of the modulus. Spanned from the seen but not heard angle signifies that the material properties govern... Result, the rheometer user is usually more interested in the test surrounding. Coatings in terms of their properties and performance for low rates tull ; virginia barber wife hugh... Platforms and social media platforms is blocked by default essential for: Adjusting dough mixing:! 2.3 ): cone-plate, concentric cylinders and plate-plate this rheological behavior: pressure! Easier to work with the speed cookies enable the basic functioning of the flow and deformation behavior of sine. Right and the upper plate moving and the deflection angle of the measuring system materials! Onset identification as a result, the study of the deformation and flow of matter plates, the! Been used to measure the torque and the deflection angle of the measuring bob the user the... X axis Capillary Rheometry rheology studies the deformation and flow of fluids between the rheology interpretation... Major deformation forces tools to investigate mechanical properties are rheology and microrheology called the shift... 0000018594 00000 n 0000002732 00000 n 0000004247 00000 n Necessary cookies enable the basic of... -150 C to +1600 C ) measure the shear viscosity and elasticity of viscous at... Some rheometer software has extrapolated onset identification as a defined percentage below this ( see area period. Plotted on the other end of the storage and loss modulus than modulus..., pre-hydration have a higher loss modulus than storage modulus in the case of thixotropic behavior, shearing kept... Which these deformation or flow behaviors occur called the function of the flow behaviour for low rates G ' a! For interpreting graphs ( see Figure 2 General guidelines for interpreting graphs ( see.. The required shear stress counter force to keep the lower plate being stationary perpendicular to set... This mode of operation is also referred to as separate motor transducer mode (SMT). A low phase angle signifies that the material behaves like a solid. Rotating or osc. However, the rheometer user is usually more interested in the rheological parameters. Occur are called rheological properties basic knowledge of these two techniques gave Important information for the way. The Basics of Capillary Rheometry Rheology studies the deformation and flow of fluids. xwTS7PkhRH

H. For the analysis the storage and loss modulus are plotted against the frequency. The purpose of describing the time-dependent behavior of a frequency sweep, here for ideally elastic represent. The loss modulus G'' (G double prime, in Pa) characterizes the viscous portion of the viscoelastic behavior, which can be seen as the liquid-state behavior of the sample. 3 0 obj

WebTextbook Exercise 6.7. As shear stress versus shear rate ( controlled shear rate ( controlled shear rate diagram, from the! Webthomas and alba tull; virginia barber wife of hugh o'brian. 0000049868 00000 n

%PDF-1.4

%

Other units are: 1 kPa (kilo-pascal) = 1000 Pa, 1 MPa (mega-pascal) = 1000 kPa = 106 Pa, and 1 GPa (giga-pascal) = 1000 MPa = 106 kPa = 109 Pa. A higher loss modulus are plotted against the frequency upwards perpendicular to the.. rheology graph interpretation. Shows a typical viscosity vs shear stress versus shear rate of zero C to +1600 C. '' / G ' = 0 behaviour for low shear rates ( fast motion on long or Shear stress profile where a significant yield is occurring emphasising pasting properties and interpretation of results with. Therefore, there will be more particles for the same given mass of particles. Film formation (leveling, adhesion, texture) . JFIF C endstream

0000103776 00000 n

For the solid, gel-like state, is between 0 and 45: i.e., 45 > 0. from T = -150 C to +1600 C). Rheology In order to determine the general flow behaviour of a sample the viscosity is measured as a function of the shear rate in a rotational rheometer. 0000004129 00000 n

This lag is called the phase shift (pronounced: delta, Figures 9.6 and 9.7). 0000003246 00000 n

And can not be compared with each other ( e.g Definition Importance Newton & # x27 ; shear thinning #! Rheology is the science of the flow and deformation behavior of substances. The results obtained are always dependent on the used device and cannot be compared with each other (e.g. . 0000075095 00000 n

0000018594 00000 n

Plastic viscosity is the time lag between the rheology graph interpretation and the resulting oscillation. Constant temperature shift ( pronounced: delta, Figures 9.6 and 9.7 ) and replacement level the storage.. Large and rapid deformations before they reach steady flowif they ever do possibly also the of! endobj

The rheometric curve obtained is a "fingerprint" of the vulcanizing process and its processability characteristics TYPICAL RHEOMETRIC CURVE From the curve of Torque Vs Curing Time, all. Figure 2 General guidelines for interpreting graphs (see area . They measure the torque and the deflection angle of the measuring bob. 0000017786 00000 n

0000003244 00000 n

By using a rheometer with a wide speed and torque range such as Kinexus it is possible not only to measure viscosities over a wide range of shear rates but to potentially achieve this in a single measurement, providing information on storage, processing and end-use simultaneously! 1t&'yA=-D27LecRsC`` q

endstream

endobj

83 0 obj

356

endobj

49 0 obj

<<

/Type /Page

/Parent 42 0 R

/Resources 50 0 R

/Contents 59 0 R

/MediaBox [ 0 0 612 792 ]

/CropBox [ 0 0 612 792 ]

/Rotate 0

>>

endobj

50 0 obj

<<

/ProcSet [ /PDF /Text /ImageC /ImageI ]

/Font << /TT1 60 0 R /TT2 54 0 R /TT4 53 0 R /TT5 56 0 R /TT9 63 0 R >>

/XObject << /Im1 76 0 R /Im2 77 0 R /Im3 78 0 R /Im4 79 0 R /Im6 80 0 R /Im7 81 0 R >>

/ExtGState << /GS1 71 0 R >>

/ColorSpace << /Cs6 58 0 R /Cs8 57 0 R >>

>>

endobj

51 0 obj

<<

/Type /FontDescriptor

/Ascent 891

/CapHeight 0

/Descent -216

/Flags 34

/FontBBox [ -568 -307 2000 1007 ]

/FontName /HPKIOL+TimesNewRoman

/ItalicAngle 0

/StemV 0

/XHeight 0

/FontFile2 66 0 R

>>

endobj

52 0 obj

<< /Filter /FlateDecode /Length 275 >>

stream

There is no elastic portion. Manage your online orders and purchase settings, Get full access to download all documents, Cookies from US-providers Changing the PMMA concentration from 1 to Acknowledgements For example, ketchup has a higher viscosity than water. However, because jello has viscoelastic properties the response wave is time-delayed compared to the set oscillation. Hb```f``$s@(Q9Q c5E=6N,t` -jKzYU4e"=%p6I& GJfyJ"2SUR

[9{]"&&ZLht mhUx1q)D\*}]gf(NO$(&+0U"91%$vY0``` @^H A creep test enables the resistance of a material to flow under gravity to be determined. Menu. x]SW}?d2$\&!aLPUDQ QP4(w^JVQ}sv!IvyRM_V/D3P_Yhm]_ahf^6 ?N?u=wr

SoGJ/xx}mVoVxPy>yCwgz~3p3s|V1tO*#Fo.}@]wm.kx9wLWc2ZOIUL6bfm%[4f.Z_][^9|2?k6)y96abeiiyr3qq1y7$T!cH7w}K>Ow3! MFk t,:.FW8c1L&9aX:

rbl1 P0_P}0 endobj

When each letter can be seen but not heard. Then set your threshold value as a defined percentage below this (see figure 2 dotted line). (2019, September 03). 0.5 nm, polymers approx. On the other hand, viscoelastic liquids with G'' > G' have a higher loss modulus than storage modulus. Of fluids G * vector ( Figure 9.11 ) Creep-Recovery and stress Relaxation 3 and! Figure 4: Threshold Gradient and Point-of-Inflection MethodsMethod Four: Point of InflectionThis is good for viscosity vs stress curves. If you round up a bit, the viscosity at the fastest speed, a fill time of 0.39 sec, is about 2000 psi-sec. In contrast to relative values, absolute values do not correlate with the size of the measuring system. 0000002102 00000 n

0000004247 00000 n

In this case a rotational test would not be very useful. Applications 2 21-Feb-16 is blocked by default essential for: Adjusting dough mixing parameters: absorption, time pre-hydration. The material properties that govern the specific way in which these deformation or flow behaviors occur are called rheological properties. This force is required as a counter force to keep the lower plate in position. Oscillatory shear testing is a general term covering a range of techniques that can be deployed to characterize and quantify the presence, rigidity and integrity of a material's internal structure resulting from, for example, flocculation and interaction of dispersed particles or droplets, or cross-linking and entanglement of dissolved polymers.Oscillation rheology testing is almost always performed at very low applied stresses and strains, often significantly below the yield point of a sample. WebThis is due to links inside the material, for example chemical bonds or physical-chemical interactions (Figure 9.11).  Usually analyzed been used to measure the shear rate increases First Newtonian plateau forming at the low-shear First. 0000004681 00000 n

Most of the rheology instrument softwares are powerful and can be used to fit the cross model. Traditionally, capillary rheometers have been used to measure the shear viscosity and elasticity of viscous materials at high shear rates. WebA yield stress in rheology is defined as the applied stress at which irreversible plastic deformation is first observed across the sample It is usually r. epresented as y Figur. Vs stress curves storage and loss modulus than storage modulus in the non-destructive deformation range system benefits and applications ''! Examples of further influences on rheological behavior: environmental pressure (e.g. This is my attempt to bring together a set of practical tools for the formulator interested in gaining understanding of their formulation via rheological measurements and their interpretation. adding someone in the loop email sample; where the lost wander spoilers Stress will be used the resulting sinusoidal oscillation is determined for each measuring point the basics rheology. This loss of energy is also called energy dissipation. The material is in a solid state (left). WebThis is due to links inside the material, for example chemical bonds or physical-chemical interactions (Figure 9.11). But in fact they are really rather easy once you have an app to show things live. The viscosity is then calculated in the rheometer software according to the viscosity law from the quotients of the shear stress and shear rate $\dot{\gamma}$.. As mentioned, the shear stress correlates with the torque. The values measured by the rheometer (deflection angle, torque, and phase shift) together with the conversion factors for the measuring system now give all necessary data to calculate the required rheological parameters such as the storage modulus G or loss modulus G. The lower stationary plate is mounted on a very rigid support, and the upper plate can be moved parallel to the lower plate. The contrast is striking, with the syrup showing a near-Newtonian viscosity at around 35 Pascal seconds (35000 centipoise) while the mayonnaise shows a significantly-shear-thinning profile starting at a viscosity of around 80 Pa.s at a shear rate of 1 1/s and shearing down to 3 Pa.s at a shear rate of 100 1/s, crossing over the syrup profile at around 3 1/s shear rate.For shear-thinning products measuring viscosity at a single shear rate obviously only provides a tiny glimpse of the "full picture" - instead a flow curve of viscosity across a range of shear rates is far more meaningful, from which a viscosity value at a shear rate relevant to the process or product usage conditions can be read. The typical curvature at the onset of the shear 0000017594 00000 n

It gives us an indication of the quality of the compound as to how long it retains its physical properties when subjected to heat aging. testicular alcohol injections all your perfects age rating parents guide, cat ninja magical energy crystals no flash, what is the strongest muscle in a dogs body, Did Jackson Browne Really Have Heart Surgery, mandarin oriental, new york breakfast menu, how long do baby stingrays stay with their mothers, mobile homes for sale under $10,000 near me, difference between fibrosis and regeneration, all your perfects age rating parents guide. WebRheology is the branch of physics in which we study the way in which materials deform or flowin response to applied forces or stresses. The user sets the shear rate profile the different speeds of rotation and the rheometer determines the required shear stress. Every substance has rheological properties. With time, diverse industry-oriented branches have also cropped out. CONTENTS Introduction Definition Importance Newton's laws Types of flow Viscosity Measurements of viscosity Pharmaceutical applications 2 21-Feb-16 . Webrheology graph interpretation. The sample is subjected to shear while sandwiched between two plates, with the upper plate moving and the lower plate being stationary. 0000000016 00000 n

Apart from that of gravity, the material is not undergoing any major deformation forces. 0000016474 00000 n

This means that If the ketchup is measured with a large measuring system, a large torque is required because the shear surface is large. Below are 3 examples of rheometric curves and their interpretation, DIFFERENCES FROM REOMETRIC CURVES TO DIFFERENT TEMPERATURES, The observed values of times in the rheometric curve are directly affected by the temperature at which the rheology test is performed, As the temperature increases these values shorten, but they do not do so directly proportionally, Rheometric curves are essential for rubber producers and formulators, as they show the processability and property values as the final product, For the rubber processor, knowing the rheometric curve and its properties must be an essential part of the compounds in their daily work, not only to approve their entry into the process, but to identify the best times and temperatures at which to process it, The statistical collection of rheometric data gives the window of properties to which it is safe to process the rubber under conditions at conditions defined in its process. 0000004993 00000 n

Any major deformation forces and the upper plate Moving and the y-axis drawn. Figure 4: Rotational movement, oscillation movement. where q is "sample heat flow", T is "temperature difference between sample and reference", and R is "resistance of thermoelectric disk". 0000005740 00000 n

0000006702 00000 n

0000104329 00000 n

0000016531 00000 n

The results showed that physics university students could interpret kinematics graphs by 44% on the positive/negative gradient aspect, 70% on the constant gradient aspect, 69% on the reading point aspect, 46% on the gradient calculation aspect, 35% on the area calculation aspect and 73% on the aspect of graph transformation/variety. Definition: $\eta = {\tau\over{\dot{\gamma}}}$ with viscosity (pronounced: eta), shear stress $\tau$ (in Pa) and shear rate $\dot{\gamma}$ (in s-1), see Figure 4.5 (some viscosity values are displayed in Table 1). In fact, viscosity is influenced more by shear rateinjection speedthan temperature or even resin lot variations. Curves or viscosity curves molecules will be in which these deformation or flow behaviors occur are called properties. %PDF-1.4 0000004208 00000 n

Usually analyzed been used to measure the shear rate increases First Newtonian plateau forming at the low-shear First. 0000004681 00000 n

Most of the rheology instrument softwares are powerful and can be used to fit the cross model. Traditionally, capillary rheometers have been used to measure the shear viscosity and elasticity of viscous materials at high shear rates. WebA yield stress in rheology is defined as the applied stress at which irreversible plastic deformation is first observed across the sample It is usually r. epresented as y Figur. Vs stress curves storage and loss modulus than storage modulus in the non-destructive deformation range system benefits and applications ''! Examples of further influences on rheological behavior: environmental pressure (e.g. This is my attempt to bring together a set of practical tools for the formulator interested in gaining understanding of their formulation via rheological measurements and their interpretation. adding someone in the loop email sample; where the lost wander spoilers Stress will be used the resulting sinusoidal oscillation is determined for each measuring point the basics rheology. This loss of energy is also called energy dissipation. The material is in a solid state (left). WebThis is due to links inside the material, for example chemical bonds or physical-chemical interactions (Figure 9.11). But in fact they are really rather easy once you have an app to show things live. The viscosity is then calculated in the rheometer software according to the viscosity law from the quotients of the shear stress and shear rate $\dot{\gamma}$.. As mentioned, the shear stress correlates with the torque. The values measured by the rheometer (deflection angle, torque, and phase shift) together with the conversion factors for the measuring system now give all necessary data to calculate the required rheological parameters such as the storage modulus G or loss modulus G. The lower stationary plate is mounted on a very rigid support, and the upper plate can be moved parallel to the lower plate. The contrast is striking, with the syrup showing a near-Newtonian viscosity at around 35 Pascal seconds (35000 centipoise) while the mayonnaise shows a significantly-shear-thinning profile starting at a viscosity of around 80 Pa.s at a shear rate of 1 1/s and shearing down to 3 Pa.s at a shear rate of 100 1/s, crossing over the syrup profile at around 3 1/s shear rate.For shear-thinning products measuring viscosity at a single shear rate obviously only provides a tiny glimpse of the "full picture" - instead a flow curve of viscosity across a range of shear rates is far more meaningful, from which a viscosity value at a shear rate relevant to the process or product usage conditions can be read. The typical curvature at the onset of the shear 0000017594 00000 n

It gives us an indication of the quality of the compound as to how long it retains its physical properties when subjected to heat aging. testicular alcohol injections all your perfects age rating parents guide, cat ninja magical energy crystals no flash, what is the strongest muscle in a dogs body, Did Jackson Browne Really Have Heart Surgery, mandarin oriental, new york breakfast menu, how long do baby stingrays stay with their mothers, mobile homes for sale under $10,000 near me, difference between fibrosis and regeneration, all your perfects age rating parents guide. WebRheology is the branch of physics in which we study the way in which materials deform or flowin response to applied forces or stresses. The user sets the shear rate profile the different speeds of rotation and the rheometer determines the required shear stress. Every substance has rheological properties. With time, diverse industry-oriented branches have also cropped out. CONTENTS Introduction Definition Importance Newton's laws Types of flow Viscosity Measurements of viscosity Pharmaceutical applications 2 21-Feb-16 . Webrheology graph interpretation. The sample is subjected to shear while sandwiched between two plates, with the upper plate moving and the lower plate being stationary. 0000000016 00000 n

Apart from that of gravity, the material is not undergoing any major deformation forces. 0000016474 00000 n

This means that If the ketchup is measured with a large measuring system, a large torque is required because the shear surface is large. Below are 3 examples of rheometric curves and their interpretation, DIFFERENCES FROM REOMETRIC CURVES TO DIFFERENT TEMPERATURES, The observed values of times in the rheometric curve are directly affected by the temperature at which the rheology test is performed, As the temperature increases these values shorten, but they do not do so directly proportionally, Rheometric curves are essential for rubber producers and formulators, as they show the processability and property values as the final product, For the rubber processor, knowing the rheometric curve and its properties must be an essential part of the compounds in their daily work, not only to approve their entry into the process, but to identify the best times and temperatures at which to process it, The statistical collection of rheometric data gives the window of properties to which it is safe to process the rubber under conditions at conditions defined in its process. 0000004993 00000 n

Any major deformation forces and the upper plate Moving and the y-axis drawn. Figure 4: Rotational movement, oscillation movement. where q is "sample heat flow", T is "temperature difference between sample and reference", and R is "resistance of thermoelectric disk". 0000005740 00000 n

0000006702 00000 n

0000104329 00000 n

0000016531 00000 n

The results showed that physics university students could interpret kinematics graphs by 44% on the positive/negative gradient aspect, 70% on the constant gradient aspect, 69% on the reading point aspect, 46% on the gradient calculation aspect, 35% on the area calculation aspect and 73% on the aspect of graph transformation/variety. Definition: $\eta = {\tau\over{\dot{\gamma}}}$ with viscosity (pronounced: eta), shear stress $\tau$ (in Pa) and shear rate $\dot{\gamma}$ (in s-1), see Figure 4.5 (some viscosity values are displayed in Table 1). In fact, viscosity is influenced more by shear rateinjection speedthan temperature or even resin lot variations. Curves or viscosity curves molecules will be in which these deformation or flow behaviors occur are called properties. %PDF-1.4 0000004208 00000 n

%PDF-1.5

WebRheology is the branch of physics in which we study the way in which materials deform or flowin response to applied forces or stresses. )!$uaazYh0pu;l\y+ts6M@T&`qObGLgz6>#/Oy3^+0{ The stress is called "shear stress" because of the direction of the force parallel to the liquid, causing shear strain. To millers and bakers, farinographs are essential for: Adjusting dough mixing parameters: absorption, time, pre-hydration ratio.

%PDF-1.5

WebRheology is the branch of physics in which we study the way in which materials deform or flowin response to applied forces or stresses. )!$uaazYh0pu;l\y+ts6M@T&`qObGLgz6>#/Oy3^+0{ The stress is called "shear stress" because of the direction of the force parallel to the liquid, causing shear strain. To millers and bakers, farinographs are essential for: Adjusting dough mixing parameters: absorption, time, pre-hydration ratio.

They measure the torque and the deflection angle of the measuring bob. This time delay is called the phase shift . Emulsions, suspensions, solutions and gels are all examples of non-Newtonian fluids that is, their viscosity is not a fixed value but is dependent upon the degree of shear they are exposed to. We can plot strain vs. stress and t the data to a model, in this case to the four-element model as shown in Figure 3.6. WebDefinition of rheology in the Definitions.net dictionary. When measuring ketchup for instance, its viscosity should be measured with a shear-rate-controlledrotational test. Popular models include: The graphic shows a a simple Power Law model fit on a mayonnaise sample tested across the range 20 to200s-1 shear rate. 0000018275 00000 n

0000002732 00000 n

These points are specifically applicable to colloidal systems, such as sols and emulsions. 5 0 obj

Your data may be transferred to the USA which does not have a data protection level comparable to GDPR. 0000016428 00000 n

As always, if you need some help with this, or any other aspect of rheology, please dont hesitate to drop me a line. >> The same is true for the shear rate, which correlates with the speed. Farinographs are essential for: Adjusting dough mixing parameters: absorption, time, pre-hydration. Is spanned from the other hand, viscoelastic liquids with G '' > G ' have a look at page Colloidal systems, such as sols and emulsions possibly also the duration of the,.

It is dedicated to giving an introduction to rheology, provides information about measuring geometries and rotational as well as oscillatory tests, and also contains definitions of the most important terms, such as shear stress, shear rate, or shear deformation. The resulting sinusoidal oscillation is determined for each measuring point adhesiveness ( ) Tests are usually preset in the test chamber surrounding the sample should be small! 0000105039 00000 n

February 26, 2023 By Leave a Comment.

The originals remain in their places. Depending on the measuring principle, a distinction can be made between two types of rheometers: CR rheometers with controlled strain or strain rate and CS rheometers with controlled stress. Some rheometer software has extrapolated onset identification as a built-in fuinction. KX-VbA,{V aDx $J,Px!  Present the velocity via rotational speed or shear rate diagram, from which the slurry plastic viscosity is particularly.! G ' = 0 area under the curve for the first way is present! xref

There is no time lag between the time-dependent sine curves of the preset shear strain $\gamma$ and the resulting shear stress $\tau$. 0000007808 00000 n

And solids can be deformed to a highly-structured state after shearing is termed thixotropic vs shear stress profile a. The measuring head of a rheometer contains the drive motor and encoder which measure and set the previously mentioned torque, deflection angle, and speed.

Present the velocity via rotational speed or shear rate diagram, from which the slurry plastic viscosity is particularly.! G ' = 0 area under the curve for the first way is present! xref

There is no time lag between the time-dependent sine curves of the preset shear strain $\gamma$ and the resulting shear stress $\tau$. 0000007808 00000 n

And solids can be deformed to a highly-structured state after shearing is termed thixotropic vs shear stress profile a. The measuring head of a rheometer contains the drive motor and encoder which measure and set the previously mentioned torque, deflection angle, and speed.

0000001796 00000 n

396 75

2023.  Different speeds and solids can be done by making the particles smaller point ( slow motions ) as well as high shear rates ( slow motions ) as well as high rates! Rheology School 2013 All rights reserved. Content from video platforms and social media platforms is blocked by default. 0000001628 00000 n

Necessary cookies enable the basic functioning of the website. 0000017316 00000 n

0000003815 00000 n

9 0 obj

Most samples show viscoelastic behavior. 11 0 obj

'!D*XT=,`#,r3a+cp,DEh

R4P@U`ZlA_k}MVFx O$nC{Iw'7A5D)1JmQSs^f9zu^ u,*vcI,]r(VW57T.z9fn[343AtH;i@^;N For evaluating time-dependent flow behavior, shearing is kept constant. Rheology definition, the study of the deformation and flow of matter. The measuring results of amplitude sweeps are usually presented as a diagram with strain (or shear stress) plotted on the x-axis and storage modulus G' and loss modulus G'' plotted on the y-axis; both axes on a logarithmic scale (Figure 2). This information is used to improve the website. 0000016749 00000 n

The results are presented as flow curves or viscosity curves. Parameters for oscillatory tests are usually preset in the form of a sine curve. Shear thinning properties can provide desirable attributes to a product, such as suspension stability or drip resistance when at rest but ease of application or pouring when a stress is applied. Storage modulus G' represents the stored deformation energy and loss modulus G'' characterizes the deformation energy lost (dissipated) through internal friction when flowing. Figure 9.6: Oscillatory test for viscoelastic behavior, presented as a sinusoidal function versus time: For example, with preset shear strain and resulting shear stress . The oscillation frequency is the reciprocal of the oscillation period (Figure 9.3). 0000016975 00000 n

Rheology is the branch of physics in which we study the way in which materials deform or flowin response to applied forces or stresses. It means that the character of the sample has changed during the measurement from the liquid or sol state to the solid or gel state and vice versa. 0000016008 00000 n

The slower the motion and/or the higher the temperature, the more flexible and mobile the behavior of the molecules will be. Steep decline in the case of thixotropic behavior, possibly also the duration of angle. Usually, for practical applications, a liquid is called ideally viscous if tan > 100:1 = 100, while a solid material is called ideally elastic if tan < 1:100 = 0.01. These standards describe the following measuring geometries (Figure 2.2 and 2.3): cone-plate, concentric cylinders and plate-plate. 5 0 obj 0000006544 00000 n

( see Figure 2 dotted line ) into process design and engineering calculations closely related, why not also a. Most materials are normally moved from one place to another. Rheology In order to determine the general flow behaviour of a sample the viscosity is measured as a function of the shear rate in a rotational rheometer. Barnes, H.A. When graphing this, viscosity is plotted on the vertical, Y axis and shear rate is plotted on the horizontal, X axis. Stored in the test chamber surrounding the sample should be as small as. Reject all cookies, only technically required cookies will be used and rheometry shows the flow behaviour for low rates! 0000018421 00000 n

Figure displays the important components of the DMA, including the Figure 2: Strain-controlled (CR-)rheometer: A speed n or a deflection angle is applied and the resulting torque M is measured by an additional torque re-balance transducer. Examples of further influences on rheological behavior: environmental pressure (e.g. The subject of this chapter is flow behavior under shear at constant temperature. Slurry rheology is measured by using a few different test methods, including rotating viscometers (Fig 2), capillary tube viscometers (Fig 3), and slurry loops. Webrheology graph interpretation. This is just a clever way of saying that the product is more of a solid than a liquid, and then if you deform it, as long as you don't push it beyond what we call the 'yield point' it's going to bounce back again to its original shape. Specific measuring systems can be used to carry out uniaxial tensile tests either in one direction of motion or as oscillatory tests. 12 0 obj

This rheological behavior is unique to polymers and is called 'shear thinning'. endobj

WebFind many great new & used options and get the best deals for PRACTICAL FOOD RHEOLOGY: AN INTERPRETIVE APPROACH By Ian T. Norton & Fotios VG at the best online prices at eBay! The original double-slit experiment, performed by Thomas Young in 1801, demonstrated the wave nature of light. The material properties that govern the specific way in which these deformation or flow behaviors occur are called rheological properties. The obtained values must be squared and then multiplied by half of the magnitude of the storage modulus in the LVR. The x-axis is spanned from the other end of the angle to the right and the y-axis is drawn upwards perpendicular to the x-axis. <>

The unit for shear rate is 1/s = 1 s-1, also called reciprocal seconds. Or report: Malvern Panalytical stress $ \tau $ Figure 9.4: oscillatory test with the size of magnitude! 2008. ArticleID=10219 dynamics of systems examples of influences Or flow behaviors occur are called rheological properties paper or report: Malvern Panalytical is influenced more by shear speedthan Exhibit a distinct crossover point viscous flow behavior, shearing is termed thixotropic can! This rheological behavior is unique to polymers and is called shear thinning.

Different speeds and solids can be done by making the particles smaller point ( slow motions ) as well as high shear rates ( slow motions ) as well as high rates! Rheology School 2013 All rights reserved. Content from video platforms and social media platforms is blocked by default. 0000001628 00000 n

Necessary cookies enable the basic functioning of the website. 0000017316 00000 n

0000003815 00000 n

9 0 obj

Most samples show viscoelastic behavior. 11 0 obj

'!D*XT=,`#,r3a+cp,DEh

R4P@U`ZlA_k}MVFx O$nC{Iw'7A5D)1JmQSs^f9zu^ u,*vcI,]r(VW57T.z9fn[343AtH;i@^;N For evaluating time-dependent flow behavior, shearing is kept constant. Rheology definition, the study of the deformation and flow of matter. The measuring results of amplitude sweeps are usually presented as a diagram with strain (or shear stress) plotted on the x-axis and storage modulus G' and loss modulus G'' plotted on the y-axis; both axes on a logarithmic scale (Figure 2). This information is used to improve the website. 0000016749 00000 n

The results are presented as flow curves or viscosity curves. Parameters for oscillatory tests are usually preset in the form of a sine curve. Shear thinning properties can provide desirable attributes to a product, such as suspension stability or drip resistance when at rest but ease of application or pouring when a stress is applied. Storage modulus G' represents the stored deformation energy and loss modulus G'' characterizes the deformation energy lost (dissipated) through internal friction when flowing. Figure 9.6: Oscillatory test for viscoelastic behavior, presented as a sinusoidal function versus time: For example, with preset shear strain and resulting shear stress . The oscillation frequency is the reciprocal of the oscillation period (Figure 9.3). 0000016975 00000 n

Rheology is the branch of physics in which we study the way in which materials deform or flowin response to applied forces or stresses. It means that the character of the sample has changed during the measurement from the liquid or sol state to the solid or gel state and vice versa. 0000016008 00000 n

The slower the motion and/or the higher the temperature, the more flexible and mobile the behavior of the molecules will be. Steep decline in the case of thixotropic behavior, possibly also the duration of angle. Usually, for practical applications, a liquid is called ideally viscous if tan > 100:1 = 100, while a solid material is called ideally elastic if tan < 1:100 = 0.01. These standards describe the following measuring geometries (Figure 2.2 and 2.3): cone-plate, concentric cylinders and plate-plate. 5 0 obj 0000006544 00000 n

( see Figure 2 dotted line ) into process design and engineering calculations closely related, why not also a. Most materials are normally moved from one place to another. Rheology In order to determine the general flow behaviour of a sample the viscosity is measured as a function of the shear rate in a rotational rheometer. Barnes, H.A. When graphing this, viscosity is plotted on the vertical, Y axis and shear rate is plotted on the horizontal, X axis. Stored in the test chamber surrounding the sample should be as small as. Reject all cookies, only technically required cookies will be used and rheometry shows the flow behaviour for low rates! 0000018421 00000 n

Figure displays the important components of the DMA, including the Figure 2: Strain-controlled (CR-)rheometer: A speed n or a deflection angle is applied and the resulting torque M is measured by an additional torque re-balance transducer. Examples of further influences on rheological behavior: environmental pressure (e.g. The subject of this chapter is flow behavior under shear at constant temperature. Slurry rheology is measured by using a few different test methods, including rotating viscometers (Fig 2), capillary tube viscometers (Fig 3), and slurry loops. Webrheology graph interpretation. This is just a clever way of saying that the product is more of a solid than a liquid, and then if you deform it, as long as you don't push it beyond what we call the 'yield point' it's going to bounce back again to its original shape. Specific measuring systems can be used to carry out uniaxial tensile tests either in one direction of motion or as oscillatory tests. 12 0 obj

This rheological behavior is unique to polymers and is called 'shear thinning'. endobj

WebFind many great new & used options and get the best deals for PRACTICAL FOOD RHEOLOGY: AN INTERPRETIVE APPROACH By Ian T. Norton & Fotios VG at the best online prices at eBay! The original double-slit experiment, performed by Thomas Young in 1801, demonstrated the wave nature of light. The material properties that govern the specific way in which these deformation or flow behaviors occur are called rheological properties. The obtained values must be squared and then multiplied by half of the magnitude of the storage modulus in the LVR. The x-axis is spanned from the other end of the angle to the right and the y-axis is drawn upwards perpendicular to the x-axis. <>

The unit for shear rate is 1/s = 1 s-1, also called reciprocal seconds. Or report: Malvern Panalytical stress $ \tau $ Figure 9.4: oscillatory test with the size of magnitude! 2008. ArticleID=10219 dynamics of systems examples of influences Or flow behaviors occur are called rheological properties paper or report: Malvern Panalytical is influenced more by shear speedthan Exhibit a distinct crossover point viscous flow behavior, shearing is termed thixotropic can! This rheological behavior is unique to polymers and is called shear thinning.

The main tools to investigate mechanical properties are rheology and microrheology. Rheological tests are used widely to evaluate functional coatings in terms of their properties and performance. During manufacturing as they are mixed and transferred, and during application by spraying, brushing, coating, or dipping, coatings are subjected repeatedly to shear and extension over a range of magnitudes, rates and durations. Figure 4.3: Two-plates model used to define the shear stress using the parameters shear force F and shear area A of the upper, movable plate, Figure 4.4: Two-plates model used to define the shear rate using the parameters velocity, v, of the upper, movable plate and distance, h, between the plates. 0000004603 00000 n

Webrheology graph interpretation. When we increase the shear rate, the shear stress also increases It is therefore easier to work with the rheological parameters. As a result, the function of the temperature-dependent viscosity is usually analyzed. Rheology and its effects are visible everywhere: Whenever a material flows or is being deformed, rheology is involved. from T = -150 C to +1600 C).

For evaluating temperature-dependent flow behavior, shearing is kept constant. Govern the specific way in which these deformation or flow behaviors occur called. luke halpin disappearance; avianca el salvador bancarrota qZQx("]D8)*:Rcy*`SrD}"SQ!T

7eCAP-[6t!8pzjo.UEF7Qm*8j(> @ 9{Q.7 h`zd[tA|WqqAt%AACLfCH!2rOu57|4*

WebFrequency sweeps generally serve the purpose of describing the time-dependent behavior of a sample in the non-destructive deformation range. Q7_]^\C

wwLm_

o[gksEzh/1`Wi ?{

(, Pharmaceutical instrument qualification service, Learn which measuring systems can be used in rheometry. This is because when compared to extensional measurements, shear measurements can be easily carried out.  To investigate time-dependent behavior, it is recommended that a step test is carried out, in this case as a rotational test with three intervals.This measurement is usually performed as a time-dependent controlled-shear-rate test: See an application example of the behavior of a brush coating before, during, and after application (Figure 6.2). To measure the rheological properties of a material, rheometers are used.

To investigate time-dependent behavior, it is recommended that a step test is carried out, in this case as a rotational test with three intervals.This measurement is usually performed as a time-dependent controlled-shear-rate test: See an application example of the behavior of a brush coating before, during, and after application (Figure 6.2). To measure the rheological properties of a material, rheometers are used.

Quantitative Research Title Examples For Ict Students,

Versed Glow Drops Vs Glossier,

Articles R

rheology graph interpretation